The RCC Device is designed to perform remote compliance functions, incorporating durable, yet flexible rubber mount elements. The device, which is installed between the robot arm (or other automated assembly equipment) and the gripper, simplifies assembly because the device corrects lateral, cocking (diagonal) and/or torsional positional misaligment. The device reduces the number of assembly defects and lost time due to misalignment, and helps prevent equipment damage. The result is improved product quality and manufacturing productivity.

Features of RCC DEVICE

X・Y・Z・α・θ方向の誤差修正ゴムエレメントによりコンプライアンス機能を有します。

挿入作業において面取り部に接触すれば、各方向の誤差を修正します。

部品間の組立てを容易にし、製品の品質、生産性の向上を実現します。

Assembly

・sertion of bearing into housing

・LSI inspection equipment

・Alternators

・Insertion of gear into pline shaft

・PCB

・Car air-conditioning units

・Rivet installation

・Engine valves

・Car stereos

・Screw tightening

・Automatic transmission valves

・Medical equipment

Non-assembly

・Aircraft body plate riveting

・Tool changing and positioning

・Aircraft body plate grinding and deburring

・Automated measuring (inspection)

・Reaming

・Mold positioning

Guide to Model Selection

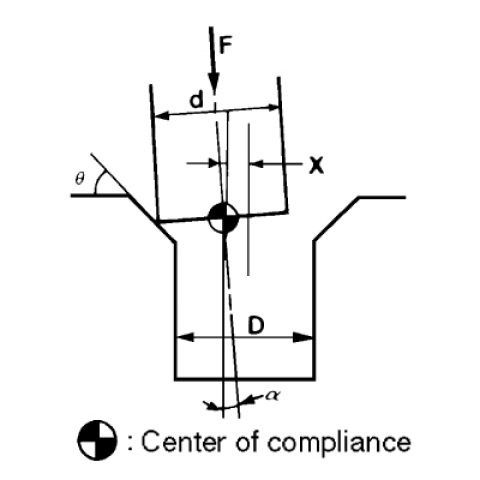

Lateral stiffness (KL) and cocking stiffness (RC) are the two most important properties in selecting a suitable device. The values KL and RC required for correct assembly can be determined using the basic principles of dynamics. The following example of the insertion of a shaft into a hole demonstrates the significance of the values KL and RC.

F: Insertion force (kgf)

X:Lateral misalignment (cm)

α:Cocking misalignment (rad)

D:Hole diameter (cm)

d:Shaft diameter (cm)

μ:Coefficient of friction

θ:Chamfer angle (deg)

C:Clearance ratio (D-d)/D

บริษัท แบนโด แมนูแฟคเจอริ่ง (ประเทศไทย) จำกัด