F-SERIES

| No. of Plies | Weight (Kg/m2) | Total Thickness (mm) | Minimum pulley diameter (mm) Knife edge | Belt support | Top friction coefficient | Backside Friction coefficient | Non-Fray | Antibacterial Antifungal | Applicable operating temperature (C ํ) | Maximun applicable width (mm) | ||||||||||

| Finger | Hot lap | Cold lap | Table | Roller | Trough | Dry heat | Wet heat | |||||||||||||

| 1 | 1.0 | 0.9 | 20/R5 | 25/RB | 80 | 〇 | 〇 | △ | 0.2 | 0.15 | 〇 | 〇 | -10~80 | 60 | 600 | |||||

〇:Suitable (functional)

△:May be suitable. Please contact Bando or your distributor.

×:Not suitable

-:Not functional

Hot joint is recommended. Delicate fabric material is used, and unprocessed belt edge and cold joint may result in unstable joint strength. and reduces the risk of foreign matter inclusion.

Non-fray specification

Suppresses belt edge fraying without additional processing,

Antibacterial, antifungal

Contributes to belt sanitation by restraining bacterial reproduction and mold generation

<Antibacterial performance>

Test sample: Coliform bacteria

Viable cell count immediately after inoculation: 250,000

After 24 hours at 35℃: 10 or less

<Antifungal performance>

Antifungal test in compliance with JIS Z2911 (5 types of fungi)

After 28 days from cultivation: up to 25% less cultivation overall

Note

Operating temperature range for belts

The operating temperature ranges for SUNLINE belts have been determined so as to take into account the strength of not only the belt itself, but also the joints. Due to the significant deterioration in strength that room-temperature gluing and finger joints exhibit at high temperatures, use of these belts under conditions that would expose them to high temperatures over extended periods of time should be avoided. They can withstand temperatures in excess of the operating temperature range for short periods of time (about 5 min.), for example to allow cleaning of the belt.

In addition, please review the dry- and wet-heat operating temperature ranges as the degree of the effect on the belt varies greatly depending on the amount of humidity present. If the belt surface temperature will range from -10 ํC to 0°C, choose a model with finger joints or hot lap joints. Models with cold lap joints should not be used under those conditions. If the belt surface temperature will range from -40°C to -10°C, choose a model with finger joints. Models with hot or cold lap joints should not be used under those conditions.

Cleaning and sterilization

Food manufacturing processes incorporate heat sterilization (using hot water or steam) that includes not only food products, but also mechanical equipment (conveyor belts) in order to ensure long shelf life and safety. Exposure of the polyurethane belts that are typically used with food products to wet heat will hasten joint damage as well as the degradation of the belt itself, eventually rendering the belt unusable. If your application includes cleaning and sterilization (with wet heat at temperatures from 80°C to 100°C), use one of the belts listed in the table to the right.

Joining Methods

SUNLINE Belts can be joined using hot or cold jointing methods. Joint types include finger, overlap, lace (fastener), but most common are finger or overlap.

Skiver joints are also possible. Please contact Bando or your distributor.

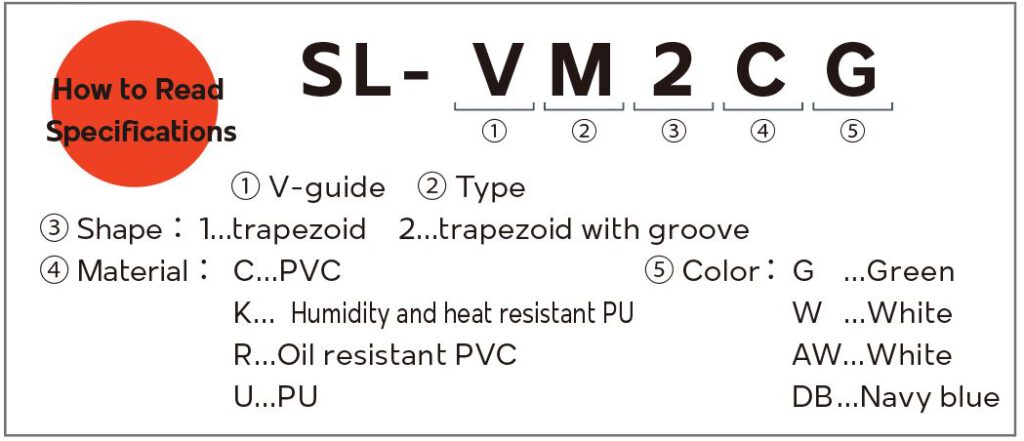

V-Guide Processing

V-guides can be used to prevent snaking. They can also be used to prevent products from falling off a conveyor by attaching them to the top of the belt, as V-guides are longitudinally Flexible.

Features

บริษัท แบนโด แมนูแฟคเจอริ่ง (ประเทศไทย) จำกัด