Description

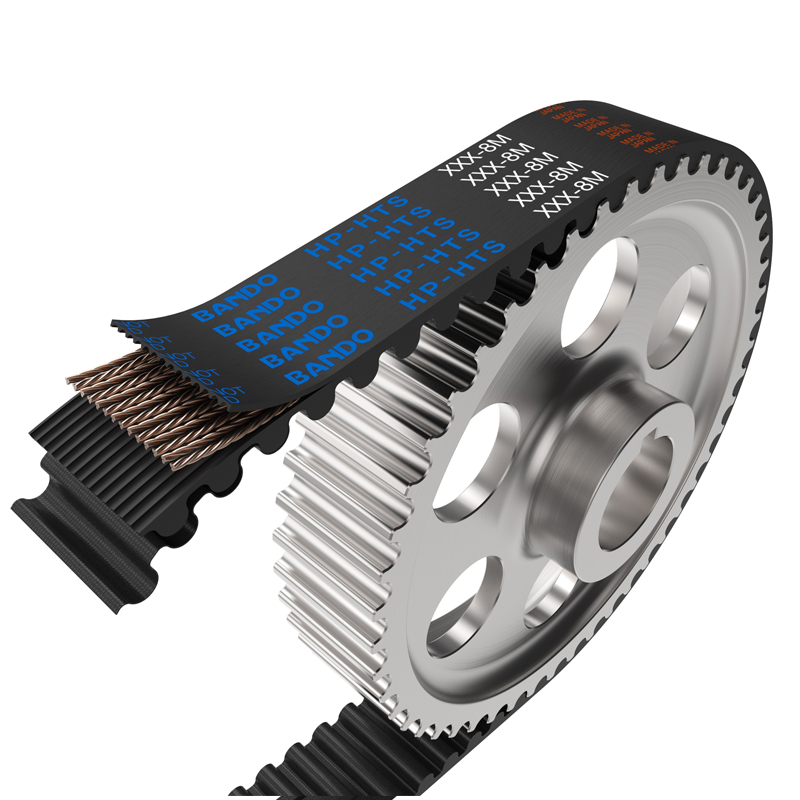

HP-HTS

(High-Performance High-Torque Synchronous Belt)

As a result of recent demands for “space-saving” of industrial machinery, we have developed “HP-STS/HP-HTS/heavy duty type belts” utilizing our long-accumulated technology and experience.

Features

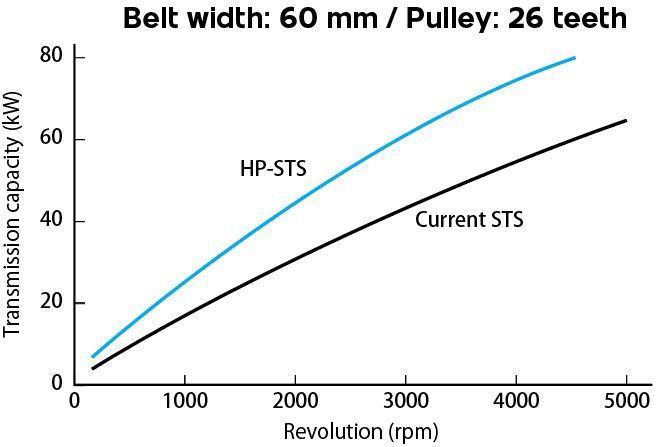

- High-torque power transmission

The HP-STS/HP-HTS belts provide higher torque and higher power transmission than normal trapezoidal teeth due to the mesh theory of the unique teeth profiles and have achieved high torque and high power transmission by using high-rigidity components. Although it varies depending on the field, it has a 1.4 to 1.8-fold transmission capacity compared to normal STS/HTS.

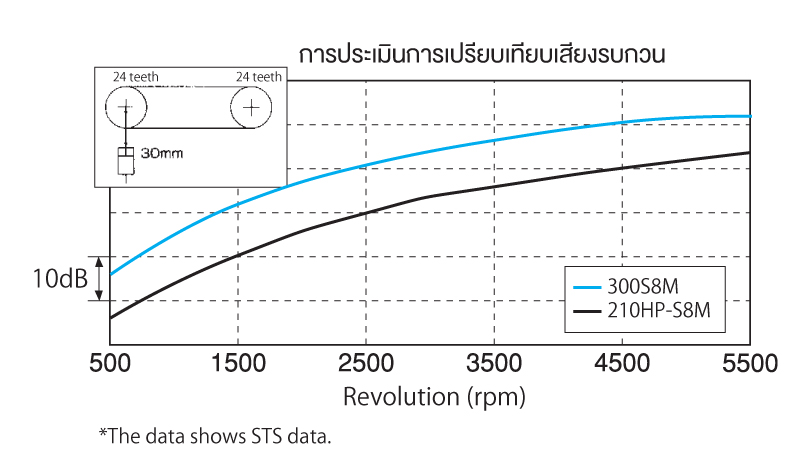

- Low noise

As the belt width can be narrower than the standard specification, the noise can be reduced.

- Miniaturized

The high transmission capacity allows a narrower width and a smaller pulley diameter than the standard specifications, allowing compact designs.

- Pulleys used

HP-STS can be used with the standard STS pulleys and TL STS pulleys.

*Manufacturable with the STS standard belt sizes. HP-HTS can be used with the standard HTS pulleys.

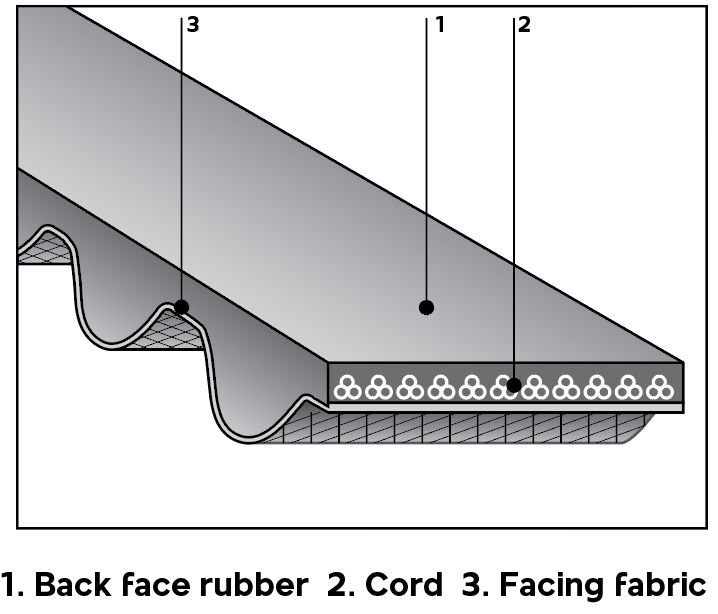

1.Back face rubber : Adoption of a synthetic rubber with little tooth deformation and high hardness

2.Cord : Glass cord taking the dimensional stability and flexibility into consideration

3.Facing fabric : Low noise is achieved by providing irregularities on the facing fabric surface and with the low frictional factor Type S14M has two layers of facing fabric, further lowering the noise and enhancing the durability. HP-S5M has a clean facing fabric specification.

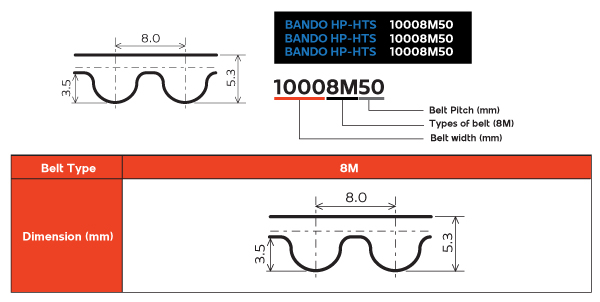

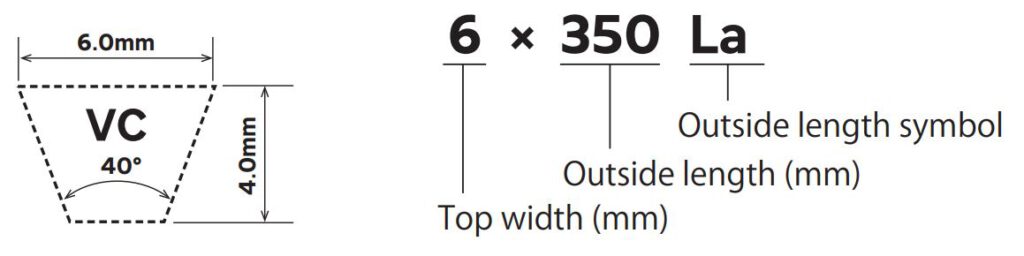

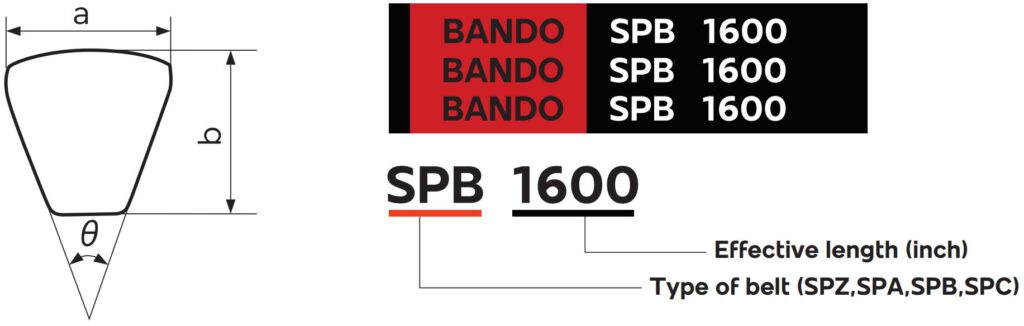

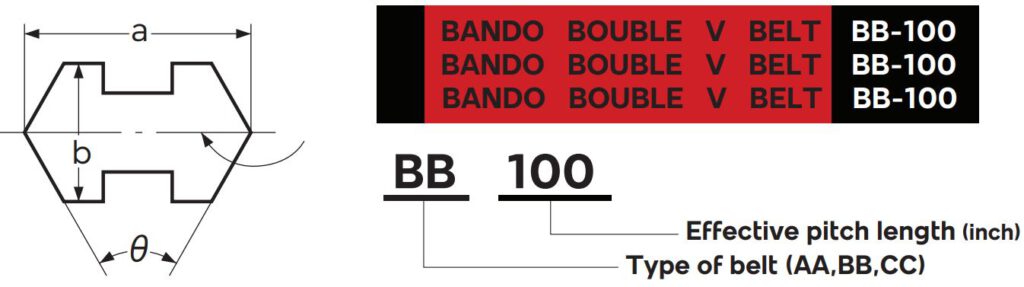

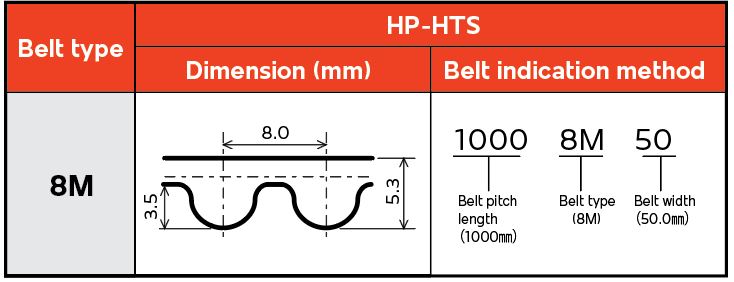

Tooth profile dimensions and indication method

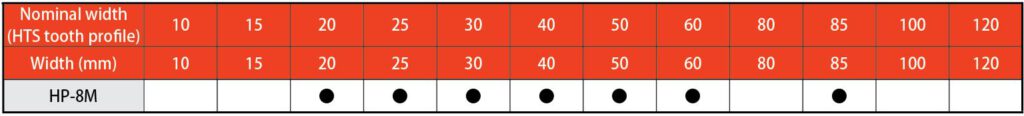

Belt standard widths

Note: For other belt widths than the above, please contact us.

* For the Stooth profile, the nominal width is ten times the belt lt width. For the HTS tooth profile, the nominal width is the be lt width.