Description

SUPER TORQUE SYNCHRONOUS

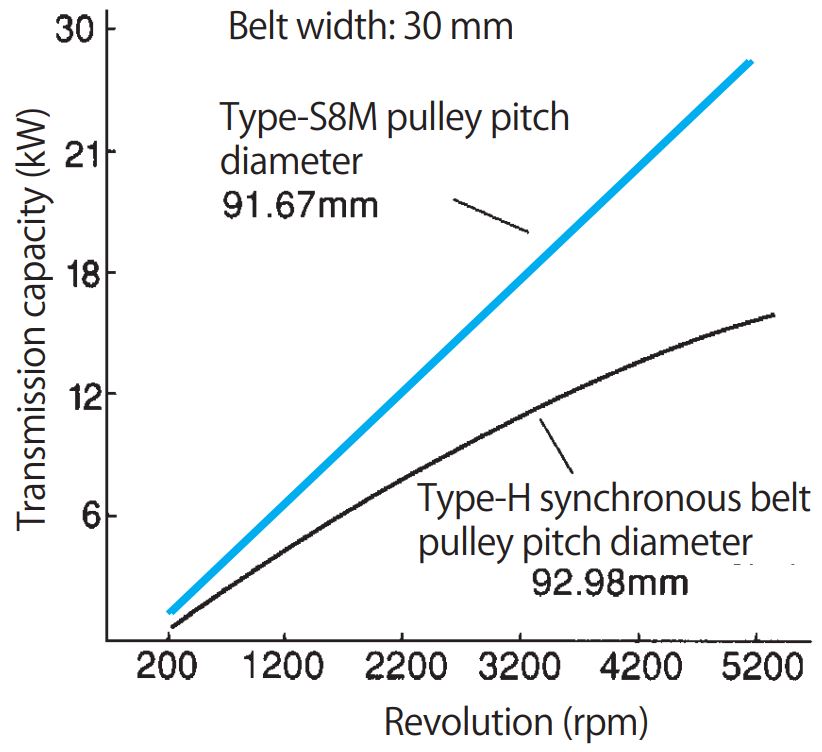

It has an arc-shaped tooth profile and smoothly meshes with pulleys without interference; hence, it provides stable performance at low speed to high speed. This synchronous belt has high transmission capability with an excellent feature that allows the belt to be designed with a narrow width.

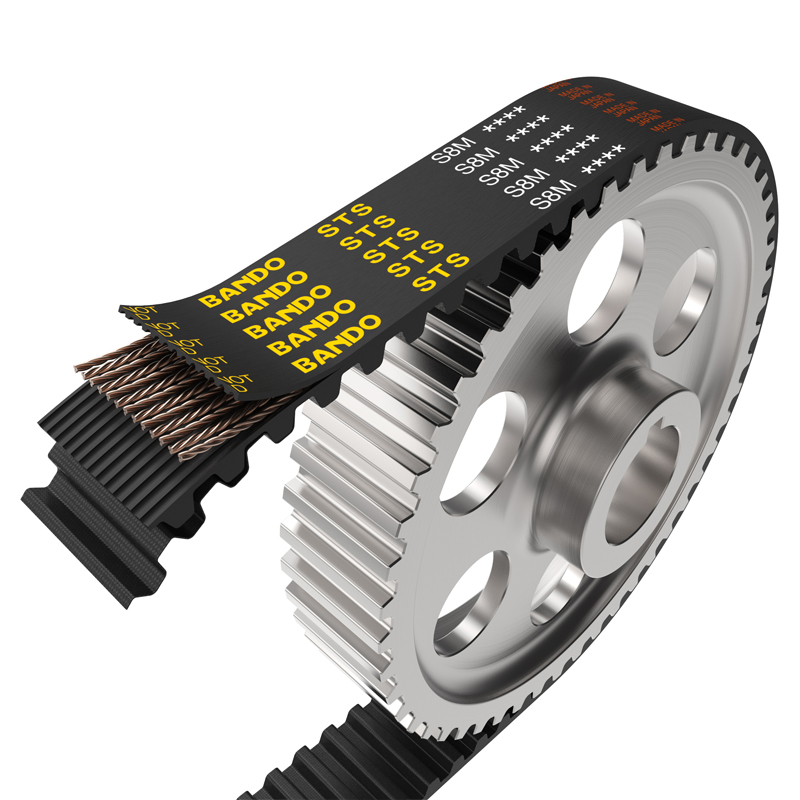

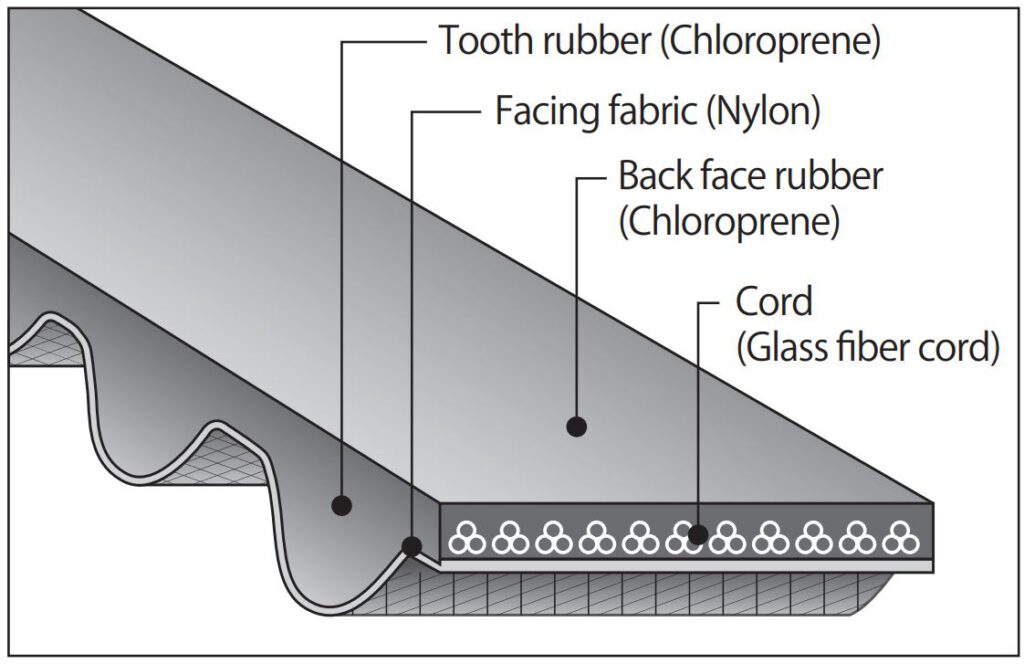

Structure

■ Back face rubber: The chloroprene rubber, which has excellent weather resistance and abrasion resistance, protects the lent weather resistance and abrasion resistance, protects the

■ Cord: Strong glass fiber cords are spirally s-twisted and z-twisted alternately, which allows little elongation and prevents side tracking of the belt.

■ Tooth rubber: The chloroprene rubber combined with the back face rubber protects the cords and provides high flex fatigue strength and excellent heat resistance, oil resistance, and weather resistance.

■ Facing fabric: The nylon woven cloth excellent in abrasion resistance protects the tooth section and smooths the meshing with the pulleys.

Features

- High-torque power transmission

The mesh theory with the unique tooth profile allows high-belt to be designed with a narrow width. torque power transmission. STS has no reduction in transmission capability at high speed and provides stable performance at low speed to high speed.

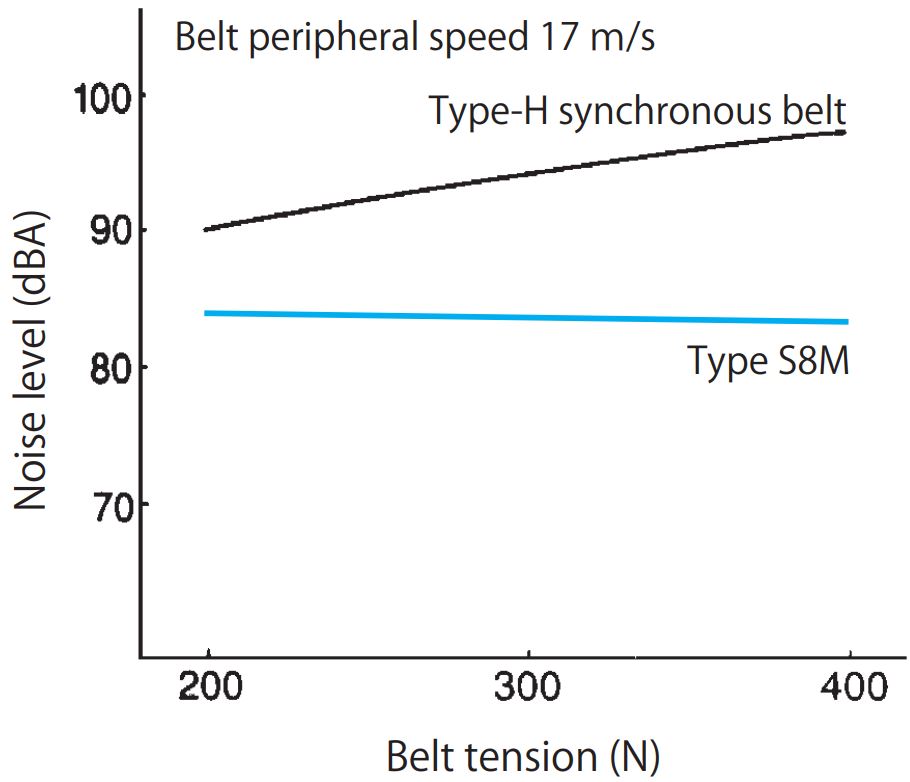

- Low noise

The smooth meshing between the belt and pulleys allows close contact between the belt tooth tip and the pulleys, leading to low noise levels.

- Long service life

The belt cords are subject to little fatigue, allowing the belt to have a longer service life than the previous synchronous belts in the same layout.

- Maintenance-free

STS has no elongation and requires no re-tensioning. In addition, it saves the trouble of lubrication.

- Cost reduction possible

The high transmission capability allows approximately 30 to 40% reduction in belt width compared to the previous synchronous belts. In addition, the eliminated need for a lubrication device, such as the ones for chains and gears, reduces the equipment cost.

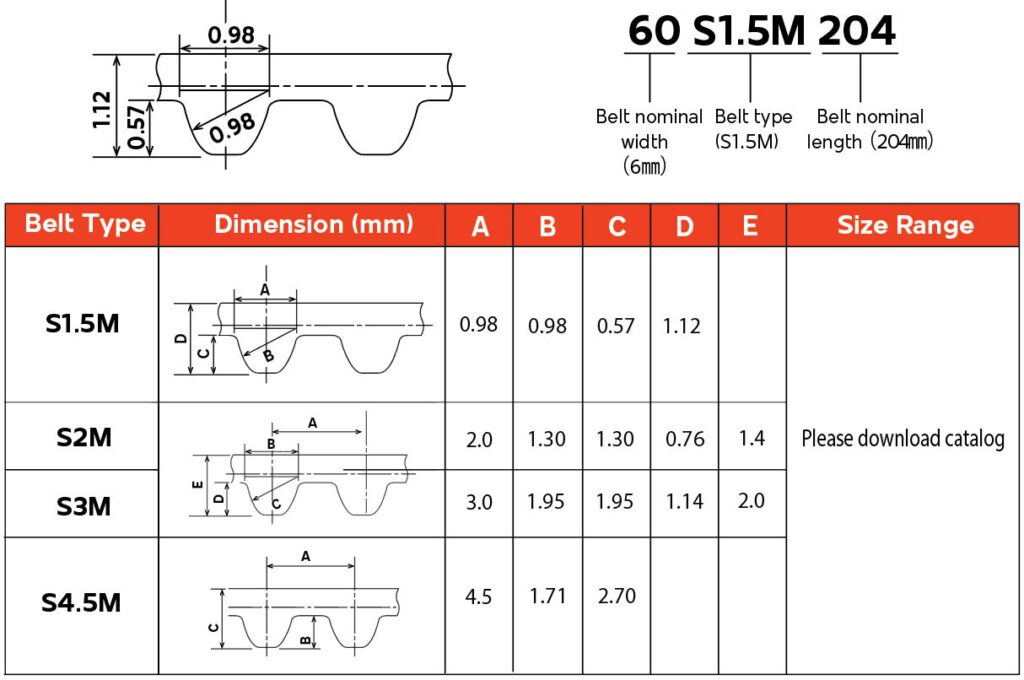

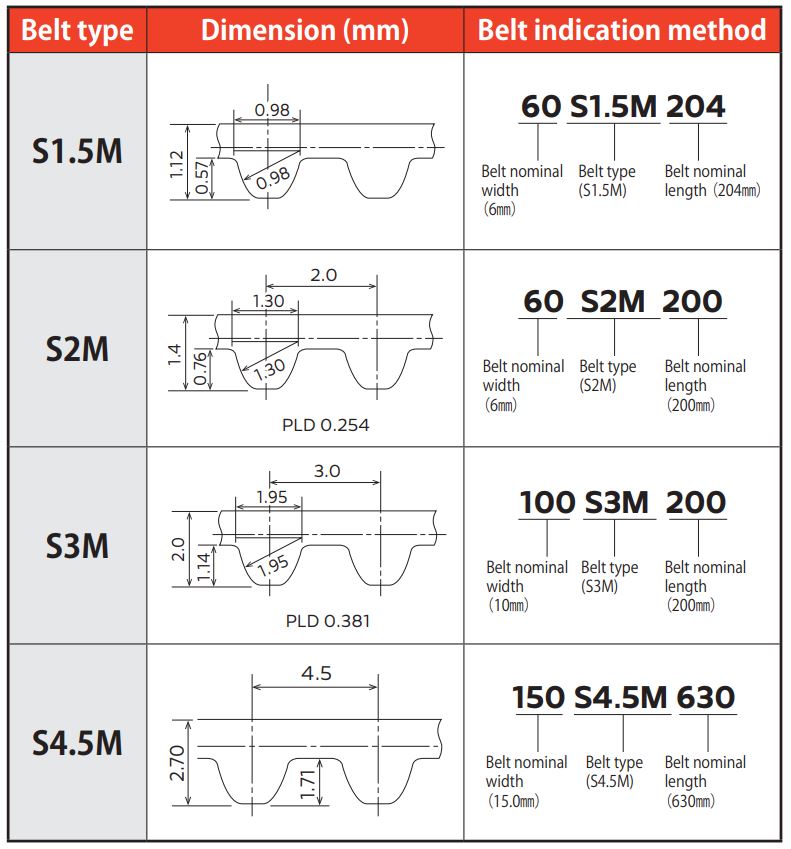

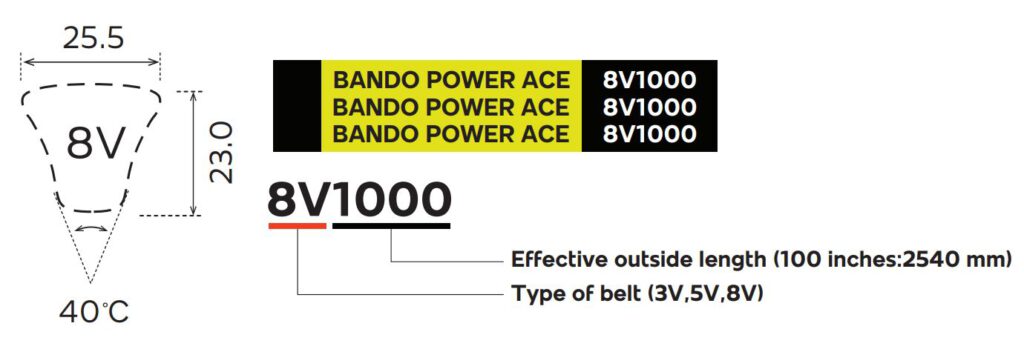

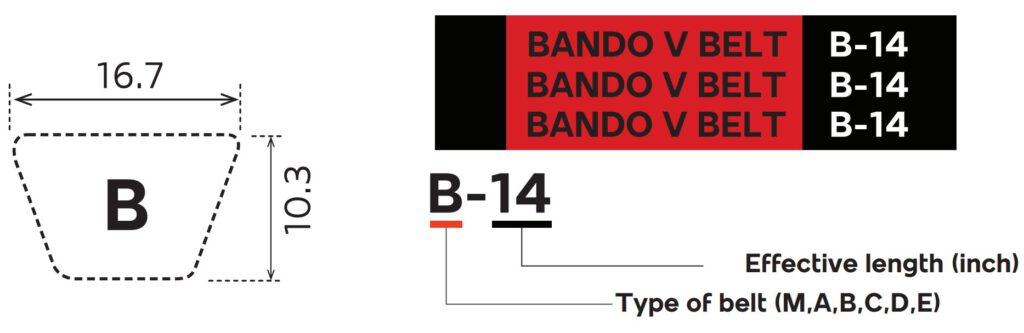

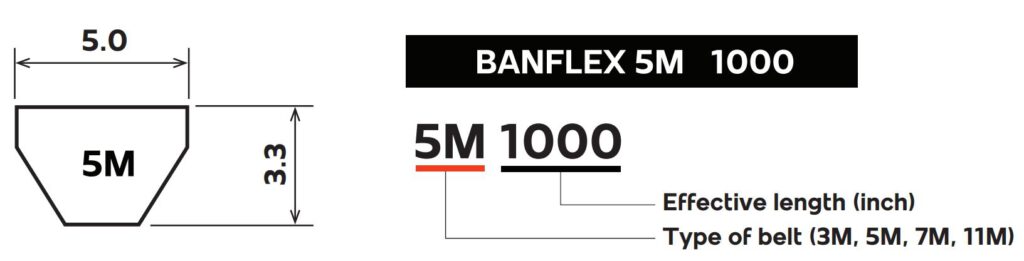

Tooth profile dimensions and indication method (rubber STS)